Raw materials Preparation

Extruded Porcelain Tiles

Keratec ceramic tiles in extruded porcelain are obtained from exceptional raw materials, submitted to a grinding process of reduced size particles and shaped by high pressure extrusion and fired at high temperatures.

In a world where specialization is a competitive advantage, the Keratec brand products are manufactured in a modern and innovative Portuguese ceramics unit of extruded porcelain floor and wall tiles, whose diversity of range and physicochemical characteristics of superior quality serve the needs of the most demanding and ambitious projects.

Pioneers in the world market, Keratec products are obtained from exceptional raw materials, which undergo a milling process of reduced granulometry and are formed by high pressure extrusion, and, finally, are fired at high temperatures, giving the product unique and high quality physicochemical characteristics.

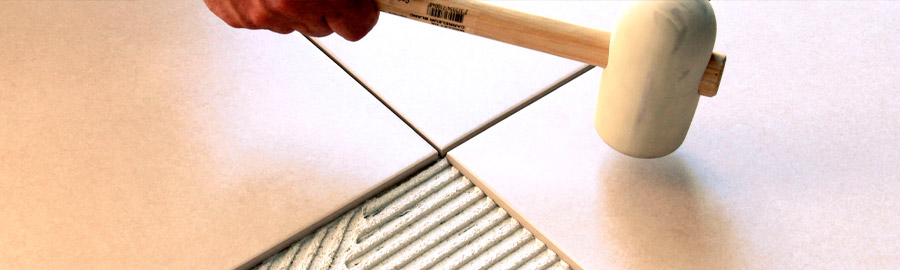

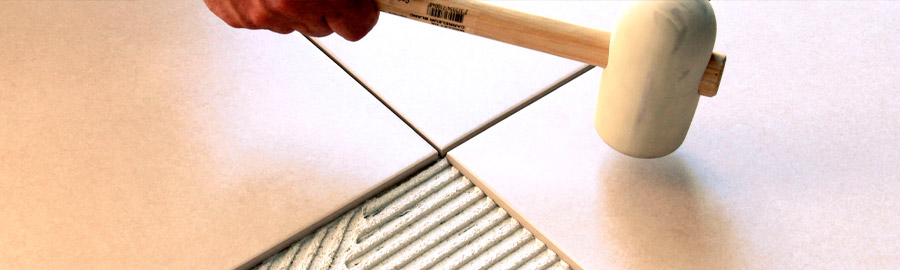

The lamellar structure that is a characteristic of the ceramic materials obtained by extrusion, results from the natural tendency of the clay particles to put themselves in layers during the extrusion process. The raw materials for extrusion are submitted to a grinding process by which a very reduced particles size is achieved, thereby increasing the density of the body (not fired yet) comparatively to the raw materials prepared to be used for pressed tiles. The smaller the particles are, the stronger is the reactivity between them, therefore lower the porosity of the final ceramic material.